Research

Drying-induced nanoparticle self-assembly

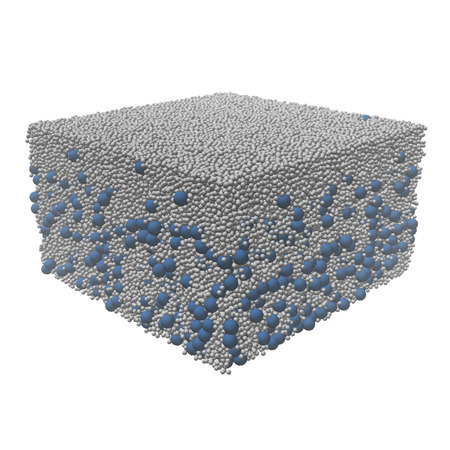

Nanoparticle-based materials are important for numerous technologies, ranging from consumer products such as paints to advanced materials used for catalysis or photonics. Often these materials are made by dispersing nanoparticles in a solvent at low concentrations, then removing the solvent by evaporation or drying to concentrate them. As the solvent is being removed, the nanoparticles self-assemble into their final solid structure due to their physical interactions and the changing concentration. The self-assembled structure, and its corresponding material properties, can depend sensitively on how the nanoparticle dispersion is processed. This is especially true when the dispersion contains multiple types of nanoparticles.

We are interested in using solvent drying to cheaply and efficiently create nanoparticle coatings or bigger “supraparticles” that have controlled composition gradients. However, it is currently hard to know what combination of parameters, such as drying rate or nanoparticle chemistry, will produce the desired structure after the solvent is removed. We are using different simulation methods, including both particle-based simulations, continuum-level modeling, and machine learning, to understand how thermodynamic and transport considerations influence drying-induced self-assembly. Our ultimate goal is to computationally design conditions that produce a targeted self-assembled structure.

This material is based upon work supported by the National Science Foundation under Award Nos. 2223084 and 2442526. Any opinions, findings and conclusions or recommendations expressed in this material are those of the authors and do not necessarily reflect the views of the National Science Foundation.

Simulation of hydrodynamic interactions in soft materials

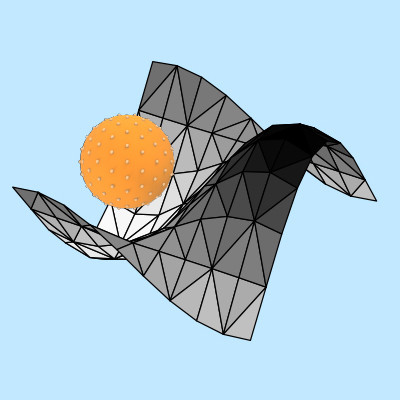

Simulating the behavior of soft materials, such as nanoparticles or polymers, suspended in a solvent is critical for addressing numerous challenges, including improving the efficiency of wastewater treatment technologies, processing advanced materials for energy applications, and effectively delivering drugs to the body. Solvent-mediated hydrodynamic interactions typically play an important role, but the solvent is difficult to model at relevant scales because of its significantly smaller size than the suspended materials. Multiparticle collision dynamics (MPCD) is a mesoscopic, particle-based simulation method that can flexibly address this challenge. We previously developed open-source MPCD software in HOOMD-blue with parallelization for both CPUs and GPUs, and we are currently working on key features needed to support new science and engineering, including:

- A more convenient and faster approach for modeling nanoparticle suspensions using rigid body dynamics

- Expanded capabilities for modeling complex boundaries as triangulated surfaces

- Methods for simulating rheology, including Lees–Edwards boundary conditions, reverse nonequilibrium simulations, and wall-driven flows.

This material is based upon work support by the National Science Foundation under Award Nos. 2310724 and 2310725. Any opinions, findings and conclusions or recommendations expressed in this material are those of the authors and do not necessarily reflect the views of the National Science Foundation.

Ultra-coarse-grained simulations of protein self-assembly

![Methodology for ultra coarse-graining [[source]](https://pdb101.rcsb.org/motm/109). Methodology for ultra coarse-graining [[source]](https://pdb101.rcsb.org/motm/109).](/images/research-ultra-cg.jpg)

Capsids are container-like structures made from proteins that form a protective shell around a virus’s genetic material. Self-assembly of the capsid plays a critical role in the virus life cycle, and understanding the dynamics of this process may provide an avenue for designing therapeutics. However, characterizing the dynamic pathway of capsid self-assembly is challenging to for experiments, but the length and time scales of this process exceed current capabilities of atomistic molecular dynamics.

To address this challenge, we are working with Dr. Chris Kieslich to develop a computationally efficient ultra-coarse-grained model, representing each capsid protein as a single coarse-grained particle, so that we can simulate capsid assembly from protein solutions at unprecedented scales. Our approach systematically integrates surrogate modeling, sparse sampling, and statistical mechanics for coarse graining to efficiently compute an accurate approximation of the pairwise potential of mean force and torque.

This work was supported by Auburn University’s Research Support Program.

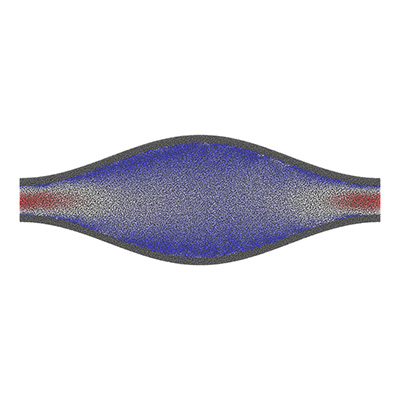

Elastic turbulence in branched and associating polymer solutions

Polymer flooding is an enhanced oil recovery method that uses solutions of high-molecular-weight polymers to displace oil trapped in reservoirs. This method has a surprisingly high recovery efficiency that is believed to be caused by a flow instability called elastic turbulence and is known to depend on the architecture and chemistry of the polymers. We are using dissipative particle dynamics and multiparticle collision dynamics simulations to study the molecular mechanisms that underly elastic turbulence. Our long-term goal is to rationally engineer better polymers for flooding processes.

Acknowledgment is made to the donors of the American Chemical Society Petroleum Research Fund for support of this research (Grant No. 66616-DNI9).

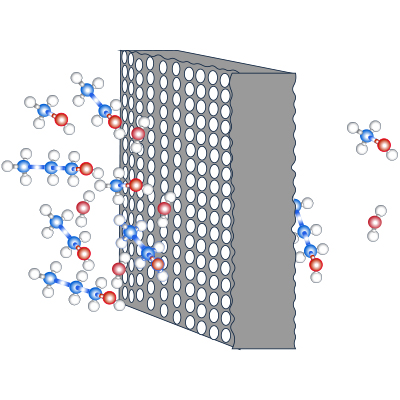

Molecular simulations of multicomponent transport in polymer membranes

Polymer membranes are an important separations technology for the chemical industry. A key engineering goal is to increase membrane selectivity to desired solutes while maximizing permeability. However, selectivity and permeability are controlled by transport phenomena that are poorly understood for industrially relevant multicomponent mixtures, in which molecular-scale interactions can nontrivially enhance or inhibit transport compared to binary mixtures. Traditional experimental approaches for characterizing multicomponent membrane-based separations yield limited information about these interactions, so we are using atomistic molecular dynamics simulations to better understanding them using binary and ternary alcohol–water mixtures as a platform fluid.

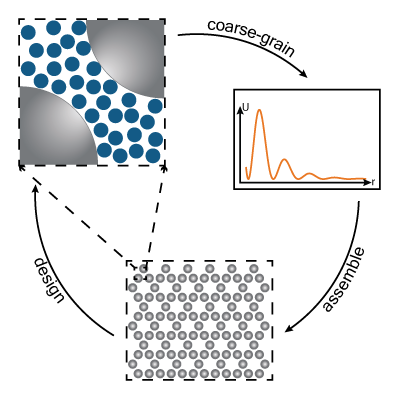

Multiscale inverse design of nanocrystal superlattices

Due to their small sizes, nanocrystals have remarkable properties that make them promising components of advanced sensors. The properties of individual nanocrystals can be enhanced and controlled by assembling them into larger ordered superlattices; however, there are limited scalable strategies for fabricating superlattices with low defect rates.

We are computationally exploring a new solvent-based strategy to address this problem. Our computational approach couples particle-based simulations with optimization methods in an inverse design strategy that aims to determine physicochemical properties of the solvent and nanocrystals that cause the nanocrystals to self-assemble into a target superlattice. We aim to make computational predictions that can be directly tested in the laboratory, so we are actively developing inverse-design strategies to enable this connection, including:

- Integrating atomistic and coarse-grained simulations in a single inverse design loop

- Using data-driven (surrogate) models to accelerate optimization

We have also developed a new software package, relentless, to carry out our inverse design calculations. We anticipate relentless will be broadly useful beyond our own application!

Materials optimization for advanced bus technologies

There is an opportunity to improve the performance and economics of advanced bus technologies by engineering their components. For example, the HVAC system can be the second-largest energy consumer in electric buses¬, and a significant portion of the energy consumed by the HVAC system is lost through windows and structural panels. Minimizing such losses may be an opportunity to decrease operating costs and downtime. We are using computational heat-transfer models to understand heat losses through components of advanced transit-bus technologies. The model will incorporate material properties of bus components that are being systematically measured by Dr. Bryan Beckingham and Dr. Cassandra Porter. We are also conducting a sensitivity analysis for the different climates found throughout the United States. This work will enable optimization of and improved decision-making about materials used in advanced bus technologies.

This work is supported by the Federal Transit Administration (Low- and No-Emission Component Assessment Program).